Welding

cialists working in PINK’s welding departments process with great precision high-grade materials like stainless steel, steel, aluminium and special metals such as Invar, titanium, Zircaloy, molybdenum, tungsten, tantalum, rhenium, niobium etc. Far from being out of the ordinary, vacuum-tight welds within the UHV and XHV ranges are part and parcel of everyday production.

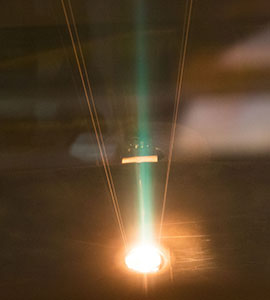

Modern electron-beam welding units

Electron-beam welding (EBW) is the only reliable joining method that meets the high quality requirements of many special applications. With its contactless mode of operation and high working speed, electron-beam welding under vacuum (without gases and additives) has numerous advantages in terms of quality and economy. In combination with electronically controlled work parameters, the constant beam diameter at the focus ensures excellent reproducibility and a high rate of progress.

Electron-beam welding unit EBW 5003/15-150 CNC

- 5,000 l process chamber volume

- Beam power: 15 kW

- Accelerating voltage: 150 kV

Welding qualifications

- Procedure test to DIN EN 288-3

- Permit for the production of pressure vessels to AD 2000 HP0

- Welding staff tested to DIN EN 287-1.

Welding processes

- TIG and MIG/MAG welding

- Microplasma welding (superfine welds in the mA range, e.g. for diaphragm bellows/corrugated tube)

- Orbital welding (closed welding systems: Ø ¼" to 2", Ø 6-57 mm, open welding systems: individually adjustable for high-purity gas lines)

- Electron-beam welding: EBW units up to max. component size (LxWxH): 2,350 x 1,400 x 1,500 mm, length extendable to max. 6,400 mm.