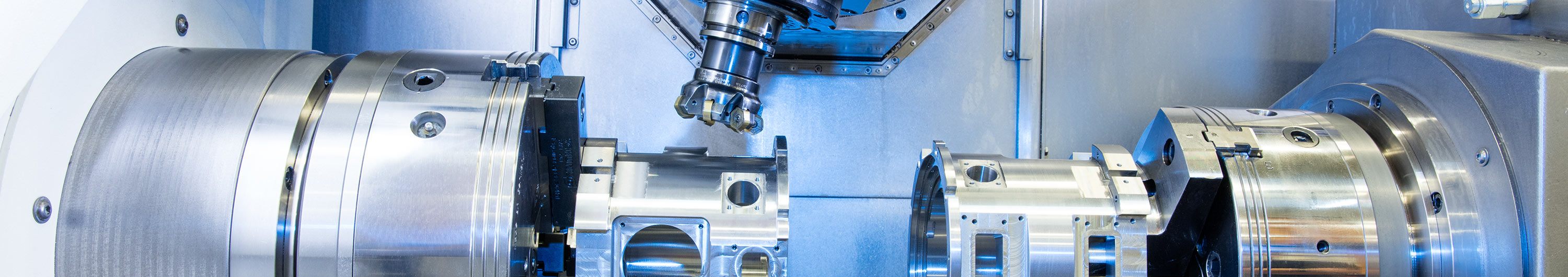

Highly advanced CNC machining centres for all requirements

PINK has 15 modern CNC 5-axis milling machines of various series, e.g. in universal, travelling-column or portal designs, as well as a turn/mill centre with a pallet changer.

PINK has special skills in the CNC machining of highly complex and high-precision workpieces.

On its CNC machining centres, PINK mainly processes high-grade stainless steels and stainless steel alloys with high-temperature strength, e.g. 1.4429 und 1.4429ESU, Inconel, Invar, Hastelloy etc. In addition, PINK has the expertise for machining numerous special materials for specific applications, e.g. titanium, molybdenum, Macor, ceramic, copper, brass, bronze and a wide range of aluminium alloys as well as various plastics.

Milling

- Max. workpiece dimensions/travel distances: X = 5,000 mm, Y = 2,100 mm, Ø = 3,400 mm

- Max. workpiece weight: 16 t

- Spindle speed: up to 18,000 rpm

- 5-axis simulation machining

- Integrated tool measurement

- Zero-point clamping systems

- 3D sensor for in-process measurement

- Tool presetters.

Deep-hole drilling

- Max. diameter: 32 mm

- Max. depth: 1,000 mm.