High-end cleaning down to the last detail

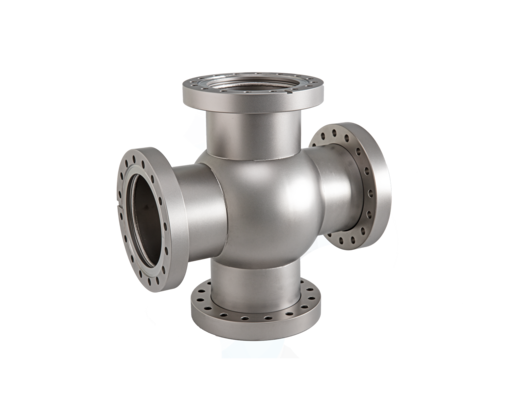

In our ultra-modern cleanrooms up to DIN EN ISO 14644-1, Class 5 and 6, we carry out cleaning services tailored to a whole range of different sectors. Using special methods, we clean both simple and highly-complex components so that they are virtually particle-free.

Cleanrooms up to

ISO class 5 and 6

Cleanroom footprint

Over 1.000 m²

Cleaning

Up to 1.7 m x 1.5 m x 1,5 m component size

Maximum precision thanks to unique cleaning processes

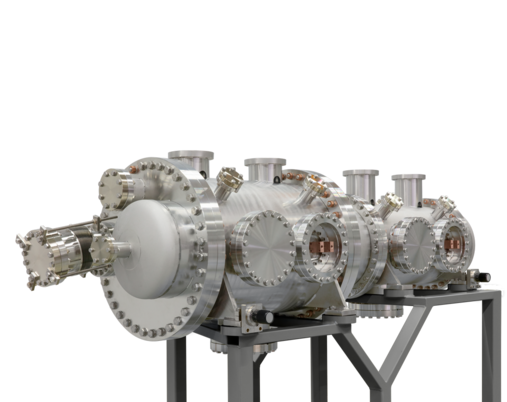

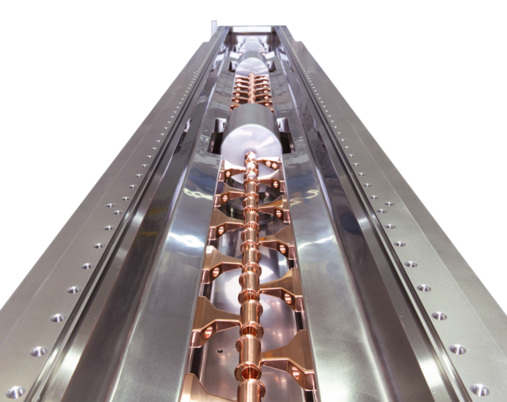

In a fully air-conditioned cleanroom area measuring more than 1,000 m², we use state-of-the-art wet and dry cleaning processes. These include ultrasonic baths, hot steam units and the dry cleaning systems we have developed ourselves. Osmosis water from our in-house treatment plant ensures virtually residue-free cleaning.

As a strategic partner of ZEISS Semiconductor Manufacturing Technology, we clean components with maximum quality in accordance with the FU1000711 specification.

Special processes for maximum cleanliness

- Bake-out with subsequent residual gas analysis (RGA) using mass spectrometer for components up to 1.7 m x 1.5 m x 1,5 m in size

- Vacuum tempering of elastomers

- Automated cooling duct cleaning

End-to-end control for uncompromising cleanliness

After cleaning, each component is subjected to comprehensive testing by high-precision measuring instruments. Ongoing monitoring of airborne and surface particle levels ensures that our cleanliness and quality standards are consistently met. Our specialist cleanliness testing and qualification processes permit the precise detection of all particles. State-of-the-art lithography systems benefit from our tailor-made solutions and precise cleaning services.