Trendsetting components for working in space

Aerospace solutions

Reliable systems in a zero-g environment

PINK Vakuumtechnik has developed and produced tailor-made aerospace solutions for the International Space Station (ISS). This page will give you an insight into examples of our expertise and versatile solution competence.

State-of-the-art supplies for international space travel

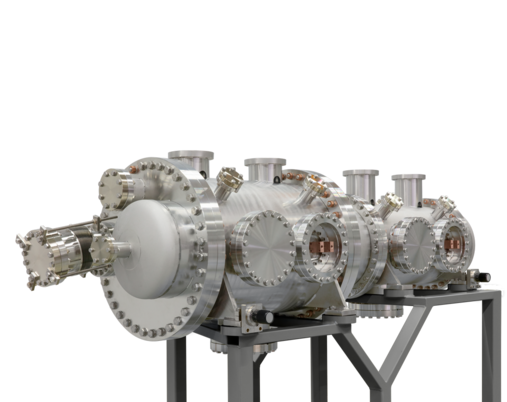

We have developed several essential key components in the field of life support for the Columbus space research laboratory on the International Space Station (ISS). The Advanced Closed Loop System (ACLS) produced by PINK on behalf of AIRBUS takes over decisive life support tasks by treating air and water. The system removes CO2 from the cabin air, generates oxygen by electrolysis and produces water from the reaction of hydrogen with CO2.

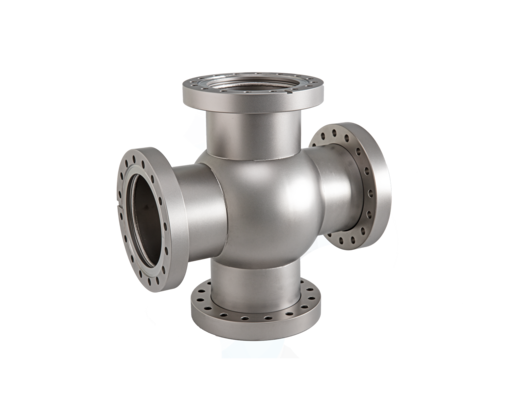

Our qualified welding processes, such as electron-beam welding, made the durable and highly resilient connections possible. In addition to the complex piping, the components were also produced by our qualified personnel and assembled under ultra-clean conditions in our cleanrooms certified to ISO Class 6. As well as comprehensive validation processes, several quality assurance tests were also carried out. Before the final implementation, the prototype TEMPUS was tested during parabolic flights.

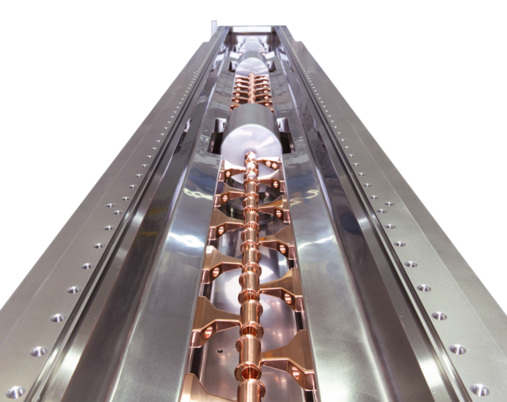

It is not only our highly-complex supply systems that are in use on the ISS – we also manufacture vacuum components and complete research modules, such as the state-of-the-art EML research module, for materials research in space under extreme vacuum conditions. This specialised high-temperature oven makes it possible to examine metals at temperatures of up to 2,200 °C under zero gravity conditions. This allows precise observation of molten metals and their behaviour in a state that cannot be simulated on earth due to the influence of gravity and wall interactions.

Thanks to this ideal environment for metal melting and solidification processes, the EML module enables ground-breaking experiments such as the analysis of sample behaviour in the liquid state as well as during cooling and solidification in order to develop new material combinations and alloys.