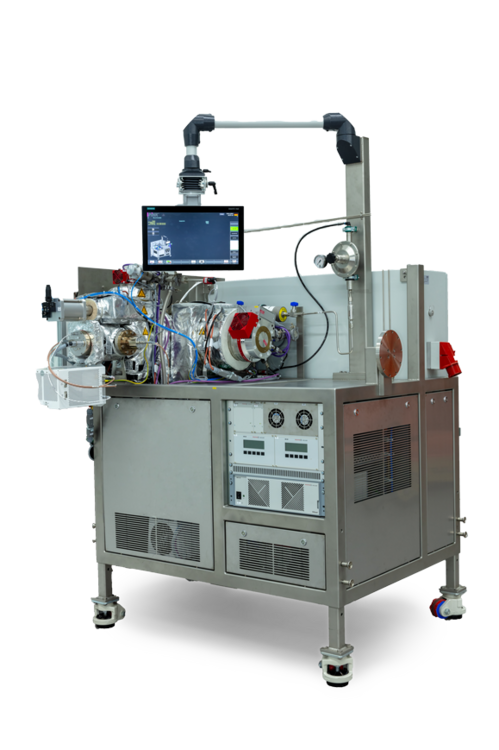

Precise residual gas analysis (RGA) for ultra-clean high vacuum

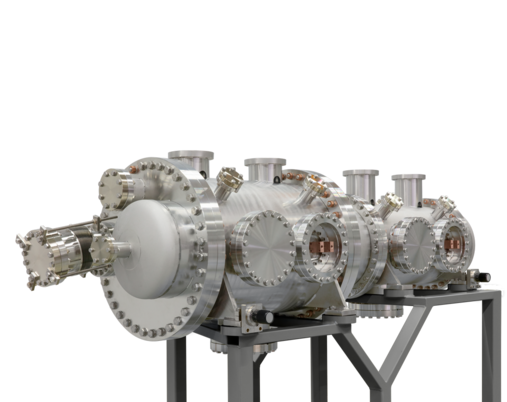

Residual gas analysis systems

Optimum vacuum properties thanks to precise residual gas analysis

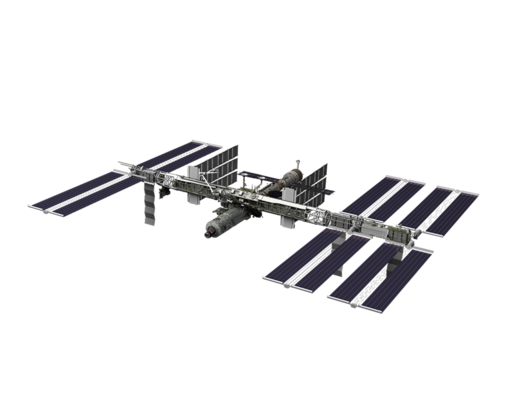

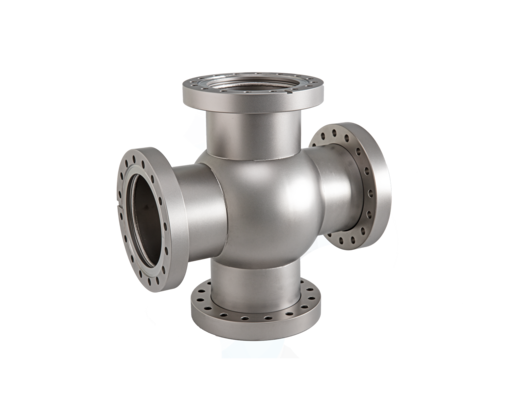

Our residual gas analysis systems offer a state-of-the-art method for optimising vacuum properties and guarantee maximum cleanliness standards in the semiconductor industry, particle acceleration and space simulation.

Bake-out temperature

up to 250° C

Measurement of residual gases

up to 512 amu

Base pressure

of ≤ 5 x 10⁻⁹ mbar

High-precision RGA technology for cleanliness analyses in high vacuum

With a base pressure of ≤ 5 x 10⁻⁹ mbar, our systems offer ideal preconditions for highly-sensitive measurements. Thanks to specific cleaning in the vacuum, desorption rates are reduced to a minimum, guaranteeing maximum cleanliness even under extreme conditions.

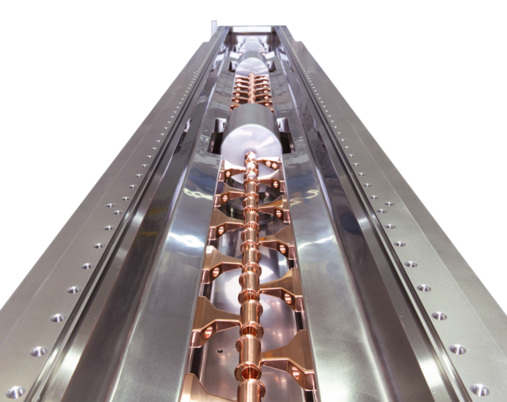

Thanks to the integrated quadrupole mass spectrometer (QMS), even the tiniest impurities are reliably detected and analysed in real time, enabling precise identification and quantification of unwanted gases.

The combination of high-resolution detection, fast data processing and intuitive control ensures complete process control, maximum operating safety and a significant improvement in the overall quality of your components.

Tailor-made residual gas analysis systems for your industry

Each of our RGA systems is adapted to your individual requirements. With an inner volume of 7.7 m³, a diameter of 1.8 m and a length of 2.7 m, we offer scalable solutions for a wide range of different sectors.

The residual gas analysis chamber can be supplemented by plasma cleaning for even higher cleaning and analysis quality. This technology improves component cleanness and optimises the long-term stability of the vacuum properties. In the semiconductor industry, in particle accelerators and in aerospace applications, this facilitates a maximum degree of process control and quality assurance.