Heat treatment and surface finish

Our high-precision heat treatment and surface finishing processes ensure optimum material properties and highest purity. Thanks to state-of-the-art high-vacuum technologies and tailor-made processes, we avoid surface reactions and achieve flawless, high-performance components.

High-precision finishing processes

Our surface finish ensures maximum precision and quality:

Thermal treatment and HV soldering

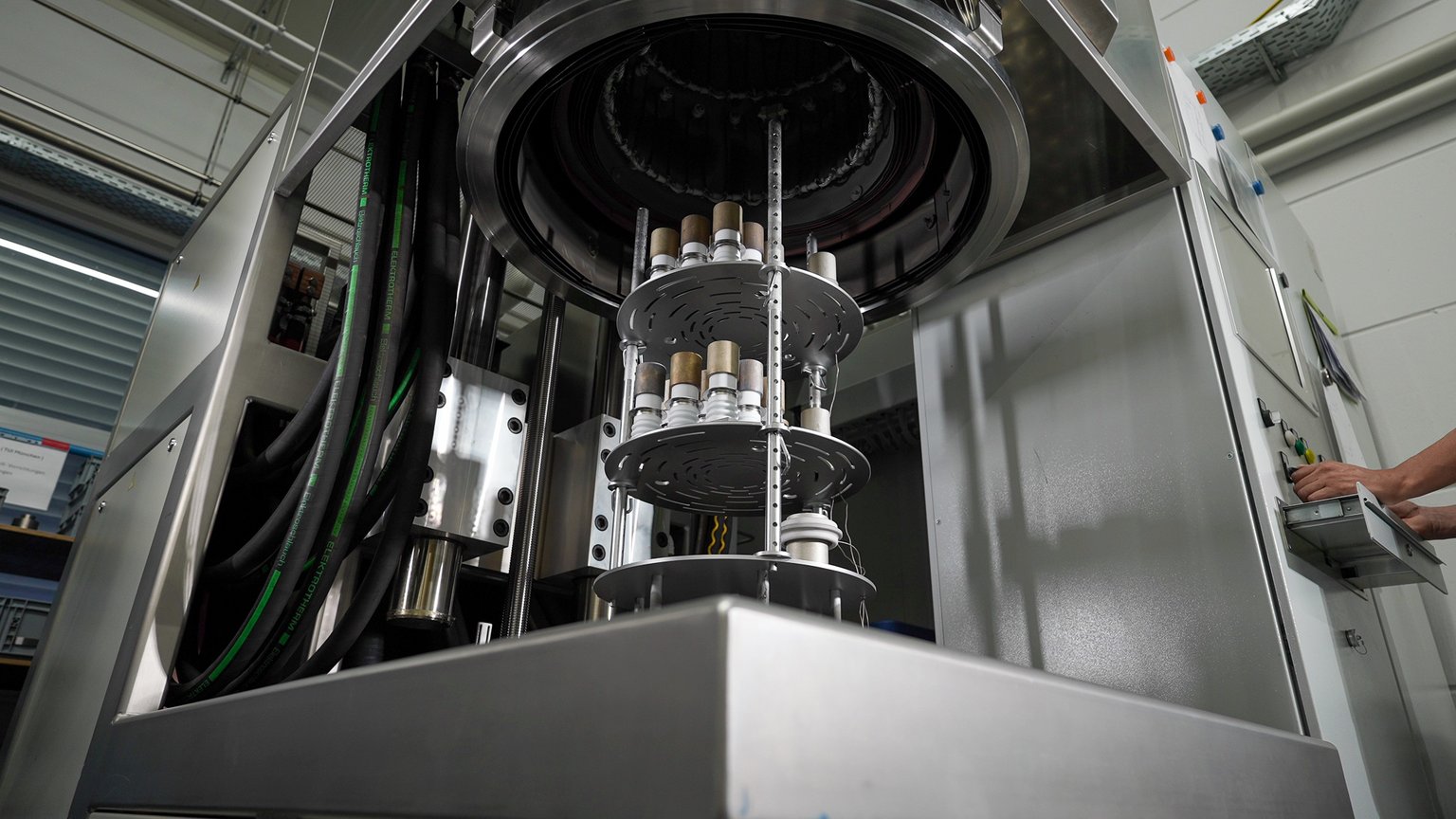

We put our expertise in high-vacuum soldering to optimum use in our own production processes. Our in-house designed and produced HV soldering ovens have been precisely matched to the respective material characteristics. They facilitate homogeneous temperature distribution over the entire component length, as well as permitting the specific setting of different temperature zones. We solder and anneal components up to Ø 400 x H 3,500 mm and 350 kg in weight at temperatures of up to 1,200 °C and a basic pressure of 1x10⁻⁵ mbar. Specific process gases can be used depending on the requirement.

We achieve outstanding material properties through precisely-controlled heating, holding and cooling phases as well as optimised annealing processes.

Our high-vacuum heat treatment processes, including stress relief annealing and low hydrogen annealing, make especially-clean processing possible. These technologies minimise surface reactions and ensure high-precision components with outstanding quality.