Test methods for maximum reliability

Quality and precision are our top priority. For this reason, we subject our assemblies and systems to comprehensive testing in order to guarantee top standards. Depending on the requirement, different testing and certification processes are used to ensure maximum safety and reliability.

Cleaning and qualification services

Particle analysis

The results are documented in dedicated measurement protocols. This method is essential for quality assurance of components used in high-precision and demanding environments, such as the semiconductor industry or aerospace engineering. Due to the very precise measurements of particles down to 0.5 µm, virtually residue-free particle testing is possible.

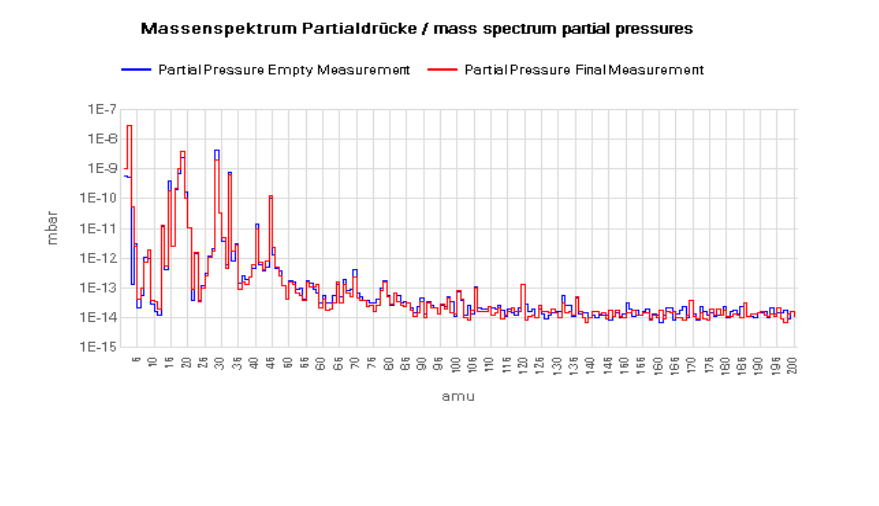

Residual gas analysis (RGA)

Every order with dry cleaning automatically includes an RGA measurement. This process enables precise analysis of the gas composition in a high vacuum and ensures that all purity requirements are met.

Customer-specific verifications

We offer a variety of methods and verifications specially tailored to the requirements of our customers. These verifications are carried out and documented in accordance with the respective specifications to ensure that all relevant quality and functional criteria are met. Before entering our cleaning process, components are tested for leaks, as required, to ensure process reliability and the protection of subsequent cleaning steps.

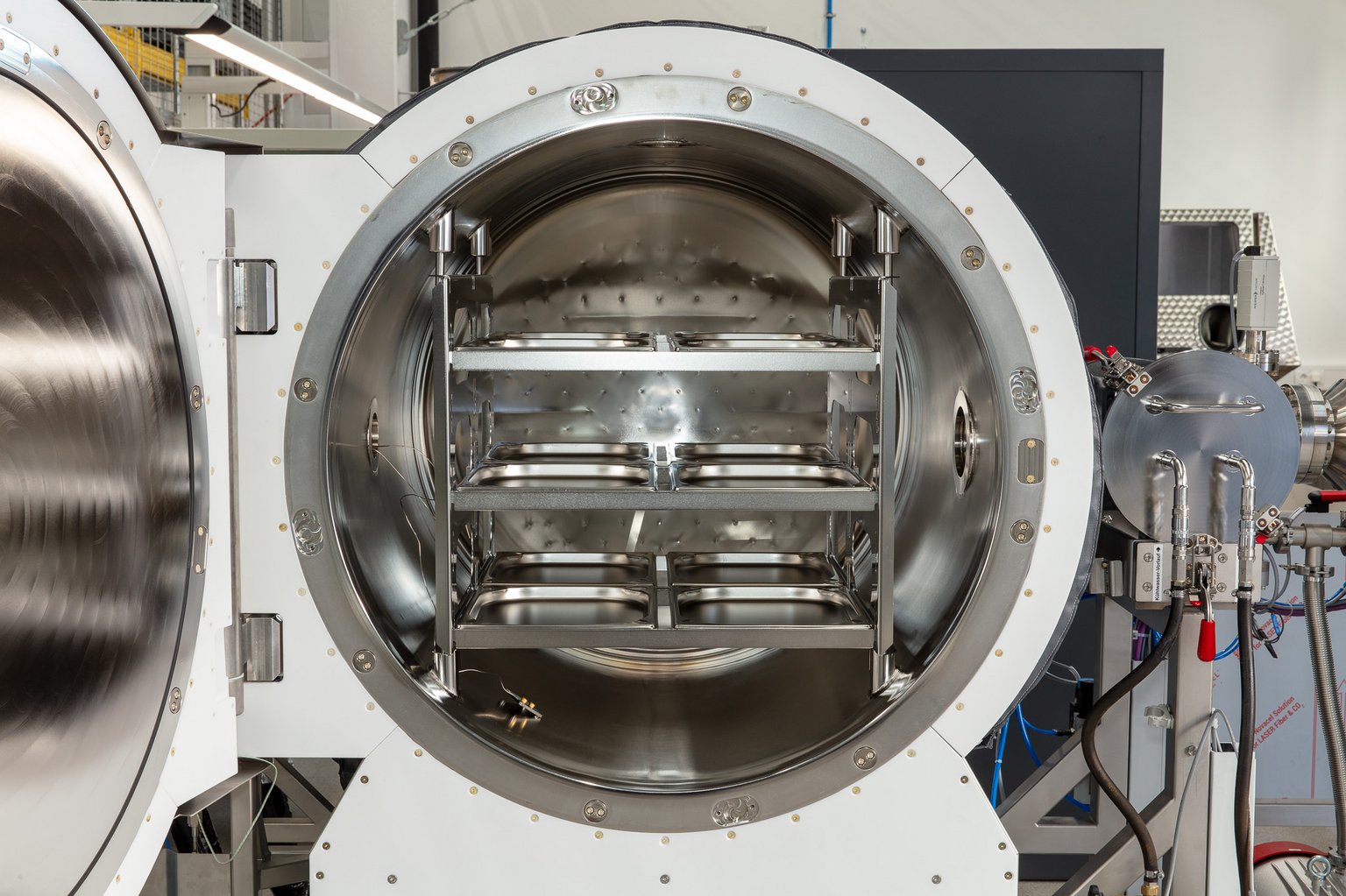

Special cleaning process under vacuum

Elastomers are heated under high temperature and vacuum in our elastomer oven to ensure the greatest possible removal of any residual production materials. This minimises possible cross-contamination in the subsequent cleaning steps.