High manufacturing depth

even for extremely complex workpieces

In our modern machine park, we carry out a wide range of processing options in material removal and non-cutting versions.

Download machine list

Excellent processing with top-grade materials

Our company offers a wide range of high-precision machining methods for lots of different workpieces and materials. With numerous state-of-the-art CNC technologies and manufacturing processes, we guarantee maximum precision and quality at every manufacturing stage. From complex milling and turning operations through the processing of special materials to advanced surface treatments.

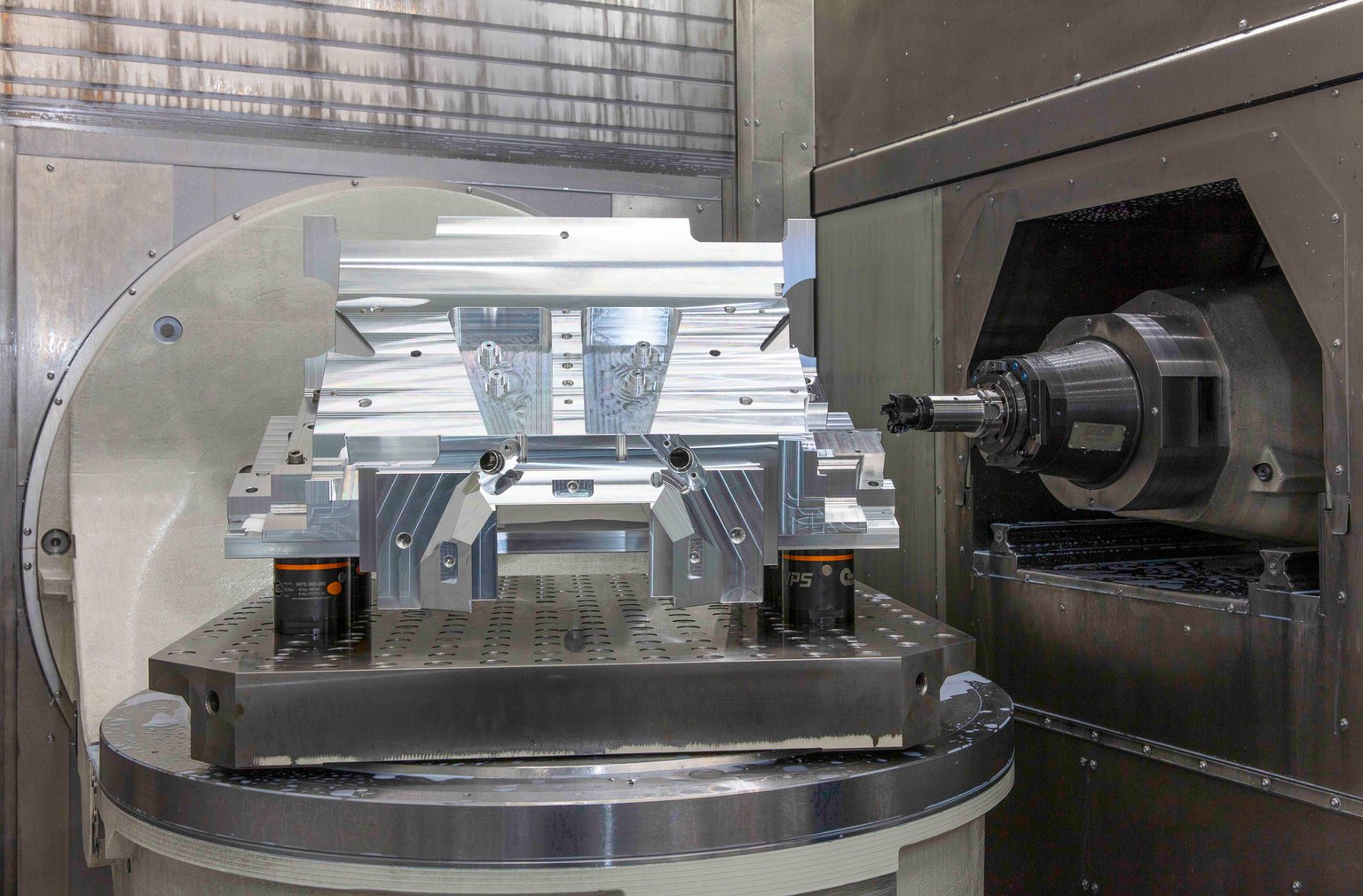

CNC machining

For turning operations, we rely on modern CNC lathes and turning-milling centres which permit the high-precision manufacturing of workpieces up to 2,500 mm in length, 1,800 mm in diameter and 5 tonnes in weight. Many of our machines combine milling and turning in one centre, so that workpieces can be machined efficiently and with the highest precision in just one clamping operation.

water jet cutting

We can also manufacture small batches and prototypes using our CNC-controlled water jet cutting equipment. Depending on the material, workpieces with a material thickness of up to 250 mm and dimensions of 4,000 x 2,000 mm can be machined.

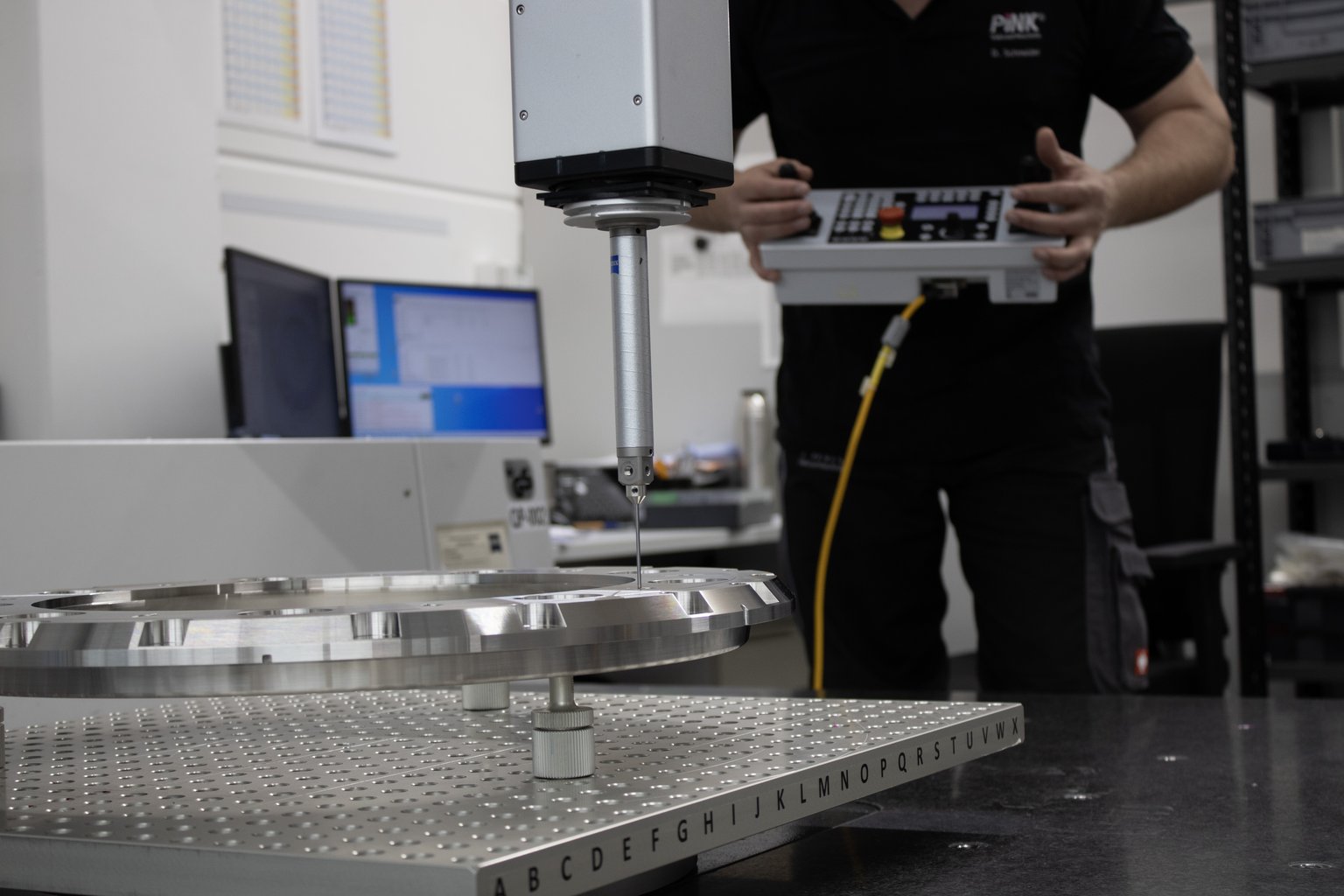

CNC milling

Our machine park includes state-of-the-art CNC 5-axis milling machines in different versions, including universal, moving column and gantry designs. Supplemented by milling-turning centres with pallet changer, they make precise machining possible for workpieces with maximum dimensions of 5,000 x 2,100 mm and a diameter of up to 3,400 mm. The machines can process workpieces weighing up to 16 tonnes.

Thanks to integrated tool measurement, zero-point clamping systems, spindle speeds of up to 18,000 min⁻¹ and high-precision 3D touch sensors, we ensure that every workpiece is produced with maximum precision.

Automation

Our automation equipment optimises the economical processing of complex machining jobs. The automated loading equipment – including Grob and Liebherr systems – enables the handling of workpieces weighing up to 1,500 kg.

Special materials and stainless steels

We process numerous materials, including aluminium alloys, high-temperature stainless steel alloys such as Inconel and Hastelloy and titanium, molybdenum and ceramics. Our long years of experience and our high-performance machine park make the machining of even the most demanding materials possible.