Precision welding of stainless steel, aluminium and little-used metals

Welding under vacuum, even in the ultra-high vacuum (UHV) range, is everyday production work for us. Our specialists carry out precision work on materials such as stainless steel, steel, aluminium and little-used metals.

Excellent processing with top-grade materials

Our expertise is based on processes tested according to DIN EN 288-3, approval for the production of pressure vessels according to AD 2000 HP0 as well as qualified specialists certified according to DIN EN 287-1. Thanks to cutting-edge technology and certified processes, we guarantee the highest precision and quality in every weld seam.

Versatile welding processes for the highest demands

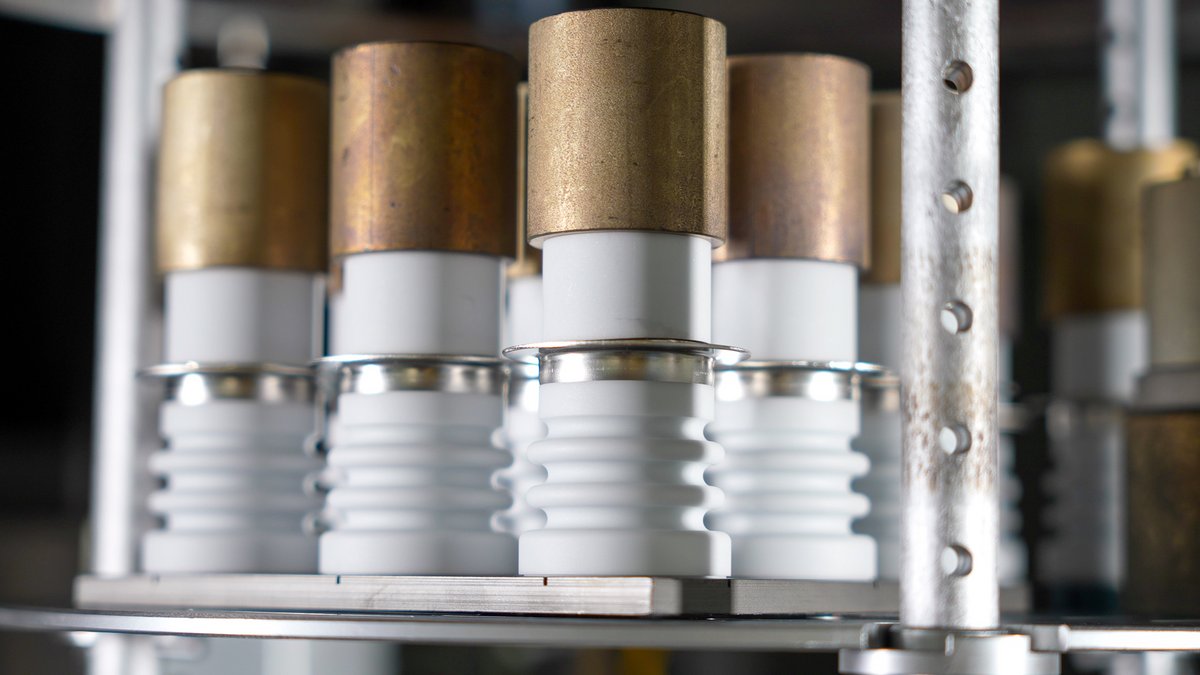

We have a command of a wide range of welding processes, optimally tailored to different applications. These include TIG and MIG/MAG welding for precise and robust joints as well as micro-plasma welding, which makes delicate weld seams in the mA range possible – ideal for welded bellows and corrugated hoses. In orbital welding, closed systems with diameters from ¼" to 2" (6-57 mm) as well as open, individually-adjustable welding systems ensure the highest quality in the processing of high-purity gas pipes.

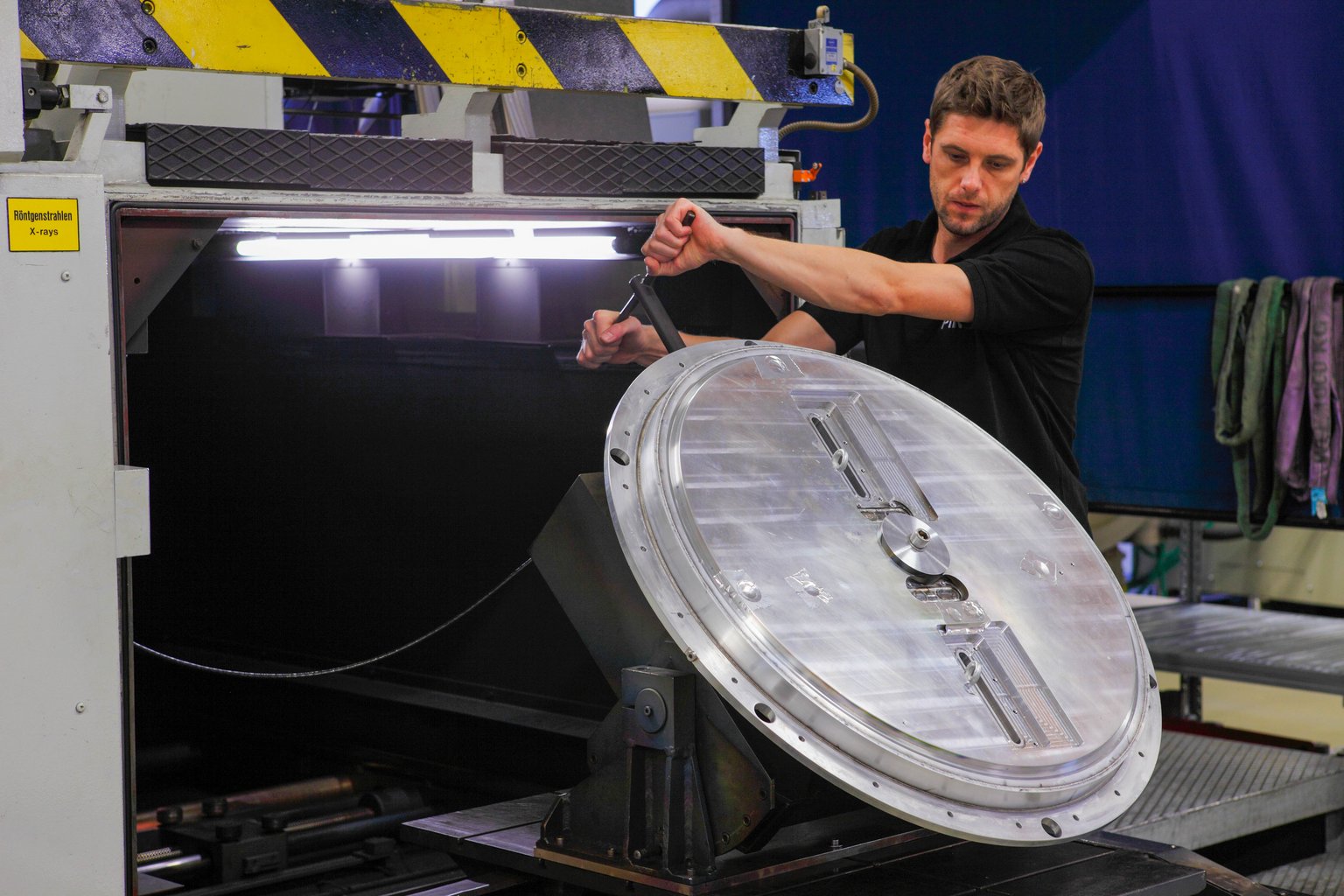

Two high-tech lines permit processing component sizes of up to 2,350 x 1,400 x 1,500 mm in a vacuum, with an extension option for lengths up to 6,400 mm. Thanks to minimum heat input, distortion is kept to an absolute minimum, while the constant beam geometry ensures maximum reproducibility. In addition, the electronic control unit guarantees outstanding efficiency throughout the contactless process.

Our special jointing technology stands for maximum precision and exceptional weld quality. Thanks to certified processes, state-of-the-art welding technologies and highly-qualified specialists, our joining process is perfect for complex components and highly-sensitive materials.