Quality engineering services from UHV specialist PINK

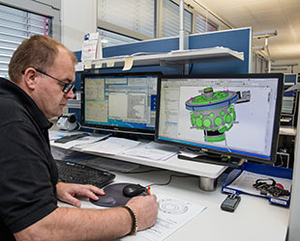

PINK’s development engineers have many years of extensive experience, particularly of the development of tailor-made vacuum technology systems even into the UHV range.

Thanks to our constant preoccupation with new tasks and the resultant development of innovations, our specialists are familiar with applying new technologies and using new materials and combining them to meet the requirements of our customers in high-precision, smooth-running and cost-effective (target costing) solutions.

Our core competence in the field of customised product design is based on a huge wealth of experience from numerous applications for leading research institutions and industrial market leaders in a diversified range of technology sectors.

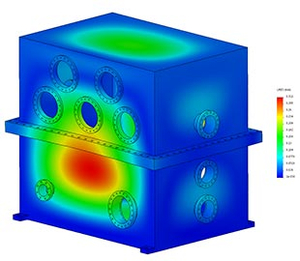

Finite element calculations

To replicate the behaviour of designed components, PINK uses the finite element method (FEM), the most widely used calculation method in the engineering sciences based on numerical approximation.

Our FEM services

- Static or tension studies

- Frequency studies

- Buckling studies

- Thermal studies

- Drop test studies

- Fatigue studies

- Nonlinear studies

- Linear dynamic studies

- Pressure vessel design studies.