For the SwissFEL linear accelerator of the Paul Scherrer Institute (PSI), PINK has developed, built and supplied a vacuum oven for high-temperature soldering. Using this system, cup-shaped elements of super-pure copper are soldered together with high precision to form 104 accelerator structures. Each of these structures consists of 113 elements, so in its final state a total of 11,752 elements will be joined together over a total length of more than 300 m and with an error tolerance of virtually zero.

Together, the copper elements form a cavity with a complex geometry into which radio waves at 6 billion oscillations per second will be fed at a later date to accelerate electron packets to close to the speed of light. The demanded precision of the soldered joints is therefore exceptional, because even the tiniest bulge of solder could cause unintended discharge.

For the new international FAIR accelerator facility, PINK is building another high-vacuum oven and will also carry out the soldering work required for the project at its own production facility. The maximum workpiece dimensions are 400 mm diameter x 3,500 mm height.

In these soldering processes, ribs and flanges are connected to the extremely thin-walled but very long beam guide tube (0.3 mm sheet thickness) to structurally strengthen and mechanically fasten it.

The outcome will be the demanded, extremely low-mass structure that creates the conditions necessary for new particle research experiments.

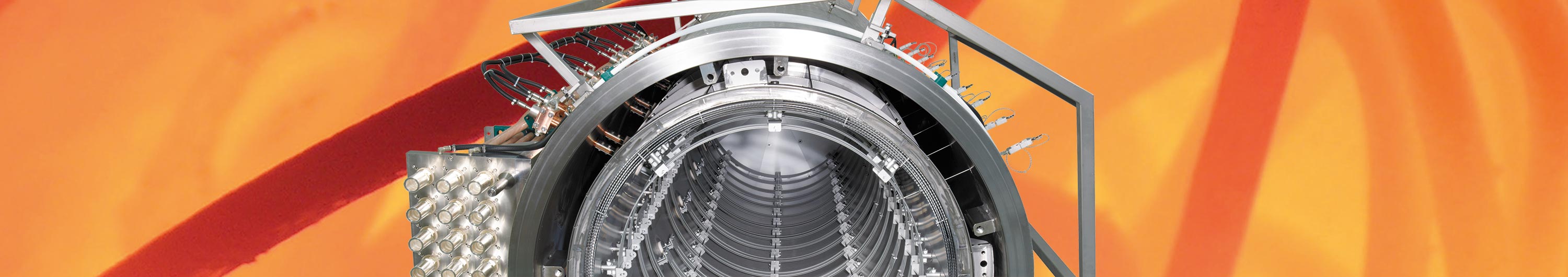

Horizontal high-vacuum cold-wall oven with water-cooled stainless steel chamber. The oven recipient (1400 mm diameter x 1500 mm) is designed for a workpiece weight of up to 250 kg and for workpiece dimensions of 1100 x 500 x 550 mm. The maximum surface temperature of the cold-wall oven is 1500 °C with a working pressure ≤ 10-5 mbar.

The 6 m tall vacuum soldering oven for SwissFEL is made largely of stainless steel. The cylindrical oven chamber can be elevated and, with its hood open, achieves a height of almost 9 metres. This special design makes it possible to vacuum-solder the vertically inserted workpiece measuring 800 mm in diameter and 2,700 mm in height and weighing a maximum of 1,000 kg.