High-performance systems supplier

PINK’s services are not confined solely to workpiece processing. As a result of our leading position in vacuum equipment manufacture, our customers can also benefit from this special expertise.

Commissioning, repairs, training and maintenance are conducted by our skilled service staff. Within Germany, we are usually available on site on the following working day.

Via our own VPN server, our service staff are able to conduct remote maintenance via a direct link. By means of this VPN link, the service specialists can access the controls and visualisations.

When existing plant is modified to boost capacity, we can offer you our expert solutions. We are also the company to contact for updating software on existing systems.

Horizontal high-vacuum cold-wall oven with water-cooled stainless steel chamber. The oven recipient (1400 mm diameter x 1500 mm) is designed for a workpiece weight of up to 250 kg and for workpiece dimensions of 1100 x 500 x 550 mm. The maximum surface temperature of the cold-wall oven is 1500 °C with a working pressure of = 10-5 mbar.

Market leader with special-purpose vacuum technology equipment

PINK has been producing vacuum technology equipment and systems to customer requirement for 30 years and has acquired a leading position in this sector.

Its comprehensive product spectrum includes UHV systems for particle accelerators, ion beam therapy units, precision coating equipment, leak test systems, high-vacuum soldering systems and much more besides.

Leading technology companies from the following sectors trust in PINK’s innovative products:

- Semiconductor and electronics industry

- Automotive industry

- Medical technology

- Optical industry

- Aerospace

- Science and research.

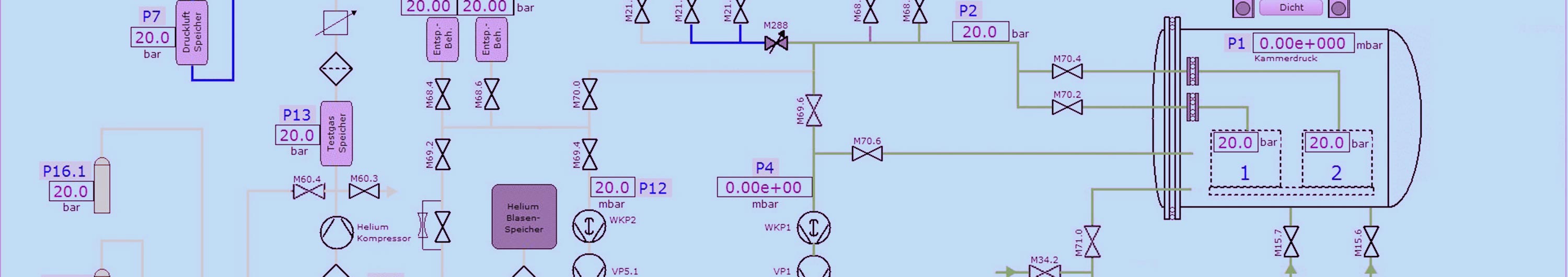

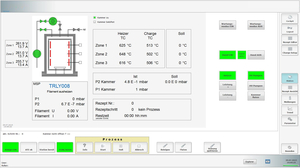

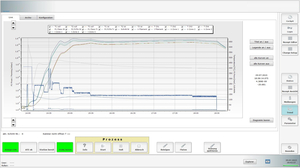

One of PINK’s core competences lies in the programming of equipment controls. The spectrum of services ranges from the automation of systems with drive control, temperature control, and control of the vacuum system and of the supply of process media through to strategies for complete, complex processes.

Programming services

- Process visualisation ranging from small PLC operator panels to graphic PC user interfaces for fully automatic process control

- Remote maintenance of the system via an encoded VPN link from the PINK’s own VPN server on its own site

- Operating data processing: recording and storage in various formats

- Links to databases

- Upgrading existing controls to the very latest standard (e.g. Siemens S5 to Siemens S7).